T-SCAN hawk

A portable solution for 3D scanning: the new ZEISS T-SCAN hawk

The portable solution for easy 3D scanning and inspection

El ligero ZEISS T-SCAN hawk con GOM Inspect

The T-SCAN hawk 3D scanner is portable, precise and has been created to make a difference. Combined with the pre-installed GOM Inspect software, it is a powerful solution that helps you every step of your way. Whether it's capturing high-quality 3D data or delivering high-quality results, it's built to simplify processes. Created for you.

Built for portable use

The compact 3D scanner T-SCAN hawk has been designed to capture data where it is needed. The lightweight, handheld solution helps you with everything from reverse engineering to quality control tasks, whether in production or on-site.

Built to be precise

The new T-SCAN hawk 3D scanner includes impressive technical features such as large object photogrammetry, multiple laser sources and three scanning modes, making it the perfect solution even for fine details or deep cavities.

The result: 3D data with maximum precision.

Created to make a difference

The new T-SCAN hawk with pre-installed GOM Inspect software is a complete solution to simplify the entire workflow from scanning to evaluation to report generation.

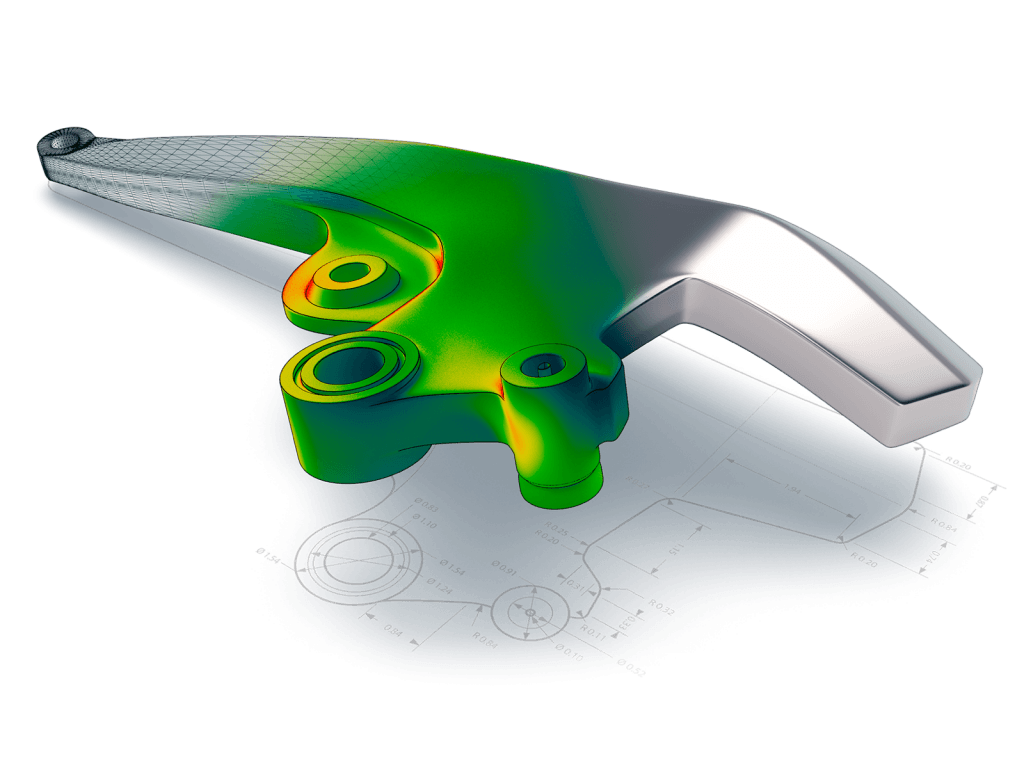

Making quality visible

GOM Inspect makes it all possible: the platform-independent all-in-one software solution enables 3D data import regardless of the measurement system. It helps you through the entire workflow, from 3D printing and reverse engineering to inspection, evaluation and reporting. It's the established standard in 3D metrology software, making workflows easier and faster.

Characteristics

Everything and anywhere

- Compact, lightweight and portable scanner design Easily transportable to help you where needed Suitable for tight spaces and hard-to-reach areas

Adapts to your needs

- Multiple laser sources for fine details and large areas Capture data from almost any surface and material For dark, reflective objects and deep cavities

Easy to use and ready to use

- Stand-alone device Ready for quick operation Easy and intuitive scanning process

Ideal for great challenges

- Suitable for scanning large or heavy objects Increased accuracy for larger objects Integrated photogrammetry Highly reliable results

Three scanning modes at the touch of a button

The flexible solution allows you to switch between scanning modes within a single scanning task.

Blue crosses for fine details

For small parts, fine details, or dark or reflective surfaces

Red crosses for large areas

For scanning large areas or fast 3D reconstructions.

Single red line for confined areas

For deep cavities or hard to reach areas

Applications

Technical data

| T-SCAN hawk | |

|---|---|

| scan mode | Standard / Single Line / Fine |

| laser source | 7 red crosses / Red line / 5 blue lines |

| Resolution | 0.05 mm / 0.05 mm / 0.01 mm |

| scan area | Hasta 550 mm x 600 mm |

| detailed scan | Compatible |

| deep cavities | Compatible |

| Dimensions | Compatible |

| Precision | 0,02 mm 0,035 mm/m |

| Scalable high-precision GOM | With integrated photogrammetry |

| Laser class (IEC 60825-1: 2014) | Class 2M (safe for the eyes) |

| Software | GOM Inspect |