T-SCAN

Your mobile measurement room

Intuitive data capture with ZEISS T-SCAN 20 and the new T-SCAN 10

A modular system for data capture without part preparation

Fast, intuitive and highly accurate

The ZEISS T-SCAN modular system is your fast track: capture 3D data without having to prepare parts in advance. Its perfectly optimized components – the T-SCAN handheld laser scanner, the T-TRACK optical tracking system and the T-POINT contact probe – form a very precise and intuitive 3D metrology solution.

In combination with the GOM Inspect software, it reaches a new dimension in coordinate measurement technology.

An all-in-one modular concept

The all-in-one modular concept and complete laser scanning solution offers maximum flexibility for a wide variety of applications and surfaces.

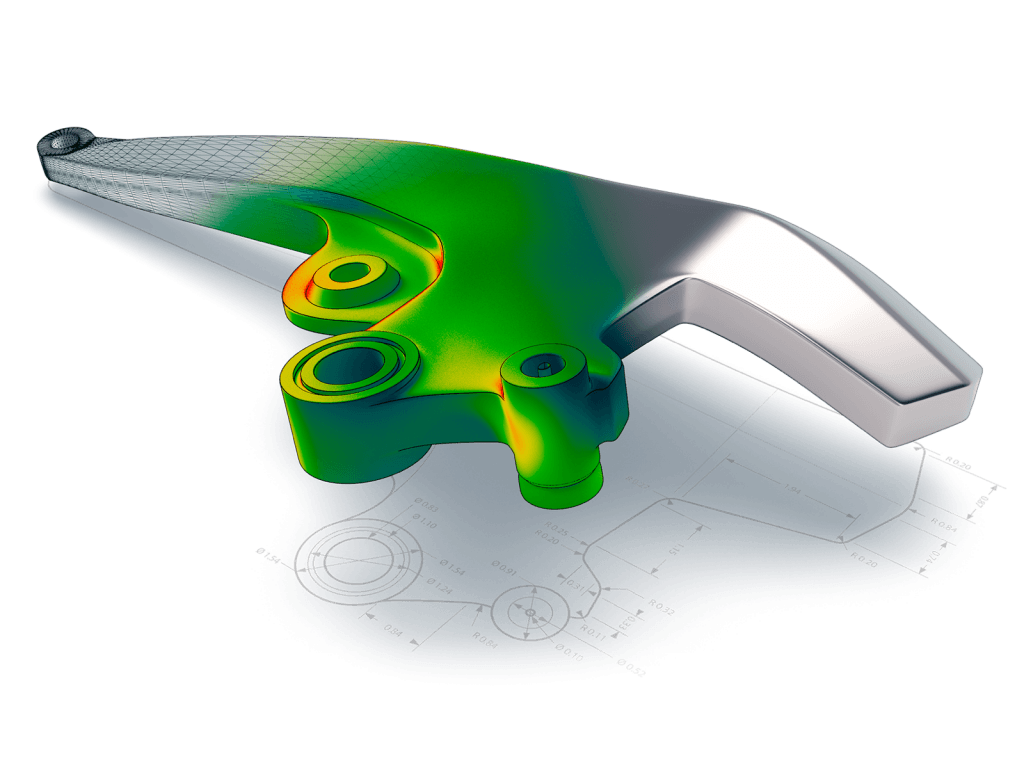

Early detection of deviations

The mobile measurement solution can be used on the shop floor and offers a very intuitive and fast way of measuring parts, analyzing them and creating digital twins.

Optical tracking for small and large volumes

Combine a T-SCAN handheld laser scanner with the optical tracking system of your choice: the proven T-TRACK 20 for large measurement volumes of up to 20 m³ or the new T-TRACK 10 for smaller measurement volumes of up to 10 m³. m³ and higher precision. If you want to quickly and reliably capture individual measurement positions, choose the T-POINT contact probe.

It is the perfect solution for single point measurements on object areas such as cropped edges and standard geometries or optically difficult to reach areas.

Software for a guided workflow

GOM Inspect Suite guides the operator through scanning, probing and inspection and enables real-time progress monitoring.

GOM Inspect: intuitive software for a simplified workflow

The modular T-SCAN system is powered by GOM Inspect, the all-in-one user-based software solution and the proven standard in 3D metrology. Measurements and inspection can be done on screen, the parametric data function makes all process steps traceable. For a simplified, faster and more productive workflow.

Applications

Technical data

| ZEISS T-SCAN handheld laser scanner | |

|---|---|

| Measurement depth | /- 50 mm |

| line width | up to 125mm |

| Average working distance | 150 mm |

| line frequency | Patient 330 Hz |

| data rate | 210,000 points/second |

| Weight | 1100 g |

| Sensor dimensions (handle and IR pins incl.) | 300 x 170 x 150 mm |

| Cable length | 10 m |

| Average distance between points | 0.075 mm |

| Laser class (IEC 60825-1: 2014) | Class 2M (safe for the eyes) |

| Software | GOM Inspect |

| ZEISS T-TRACK 10 | |

|---|---|

| Measurement distance: object-camera | 2.0 m – 4.50 m |

| Measurement volume | 10 m³ |

| Field of view | Hasta 2894 mm x 2324 mm |

| Measurement rate | up to 2.8kHz |

| Weight | 18.5 kg |

| Dimensions | 1150 x 180 x 150 mm |

| Software | GOM Inspect |

| traceable accuracy | 10 m |

| Precision | 0.033 mm 0.033 mm/m |

| ZEISS T-TRACK 20 | |

|---|---|

| Measurement distance: object-camera | 2.0 m – 6.0 m |

| Measurement volume | 20 m³ |

| Field of view | Hasta 2894 mm x 2324 mm |

| Measurement rate | up to 2.8kHz |

| Weight | 18.5 kg |

| Dimensions | 1150 x 180 x 150 mm |

| Software | GOM Inspect |

| traceable accuracy | And |

| Precision | 0.04 mm 0.04 mm/m |