TECHNOORG LINDA products for MECHANICAL SAMPLE PREPARATION

Microsaw

Precise cutting tool.

Microheat

Bonding of thermoplastics under a stereoscopic microscope.

Micropol

Polisher for small TEM and SEM samples.

HSS tool

Custom made mechanical hand tools.

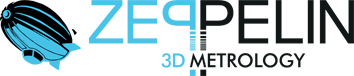

Microsaw

Precise cutting tool.

Dedicated slicer for sectioning smaller TEM and SEM samples.

It is a specially designed tool to cut almost any solid state material with an accuracy of 0.01mm.

- adjustable in 3 directions to be used under stereoscopic microscope continuously variable rotation speed

Adjustable in 3 directions

In order to have the most suitable cutting position, the sample holder can be adjusted in all directions with an accuracy of 0.01 mm.

Microsaw

Precise cut under stereo microscope.

- PreciseSmallEasy to use

APPLICATIONS

Microsaw is a small and versatile diamond circular saw that mounts under a standard laboratory microscope. The precision offered by such an optical alignment makes the Microsaw ideal for the cutting and sectioning required during TEM sample preparation. Due to the compact design and easy operation, Microsaw allows the user to cut almost any solid material reproducibly and quickly before thinning it for TEM. Thin semiconducting and ceramic materials, hard metals can be further sectioned with an accuracy of 0.01mm.

OPERATION

The Model MS 3 Micro Saw is driven by an electric motor through a worm drive. The power supply subunit provides 12 V DC. The speed at which the wheel spins is continuously adjustable. It is possible to adjust the position of the sample, the point of contact of the arm, the tension of the arm and the control mechanism of the bottom stop. Two adjustment screws on the bottom of the instrument allow the stand to be positioned and the Microsaw to be leveled under the stereo microscope for precision cutting.

SPECIFICATIONS

- Power input: 12V DC, 1.5A Power consumption: 18W Dimensions: 260 x 150 x 80mm Diamond wheel Type: AC32 63/50 Dimensions: 50mm diameter, 0.17mm thickness max. sample size: ~ 10 x 10 mm Speed range: 35 - 410 rpm min. slice thickness: ~ 100 microns

SYSTEM CONFIGURATION

- Switching power supply Input power: 100 - 240 V, 50 - 60 Hz Output power: 12 V, 30 VA Micro saw device includes 1 diamond wheel

-

REPLACEMENT PARTS

- Diamond Wheel (Part No.: MS-DW)

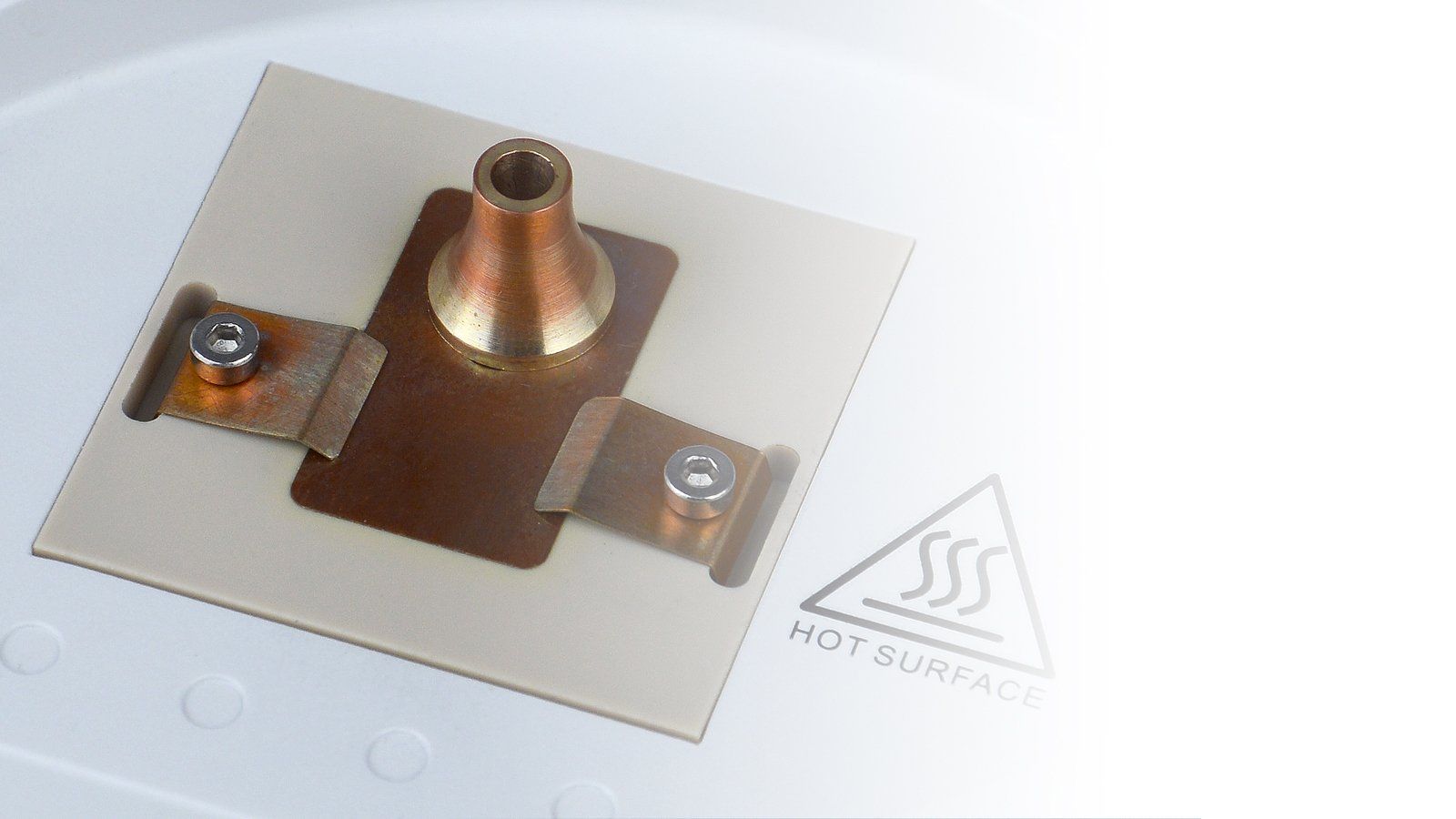

Microheat

Bonding of thermoplastics under a stereoscopic microscope.

Microheat

Thermostabilized heating plate for easy embedding of samples and bonding of thermoplastics.

- continuously adjustable small temperature

Little

Due to the small dimensions, it can be easily placed under the stereo-optic microscope and in this way bonding failures can be avoided.

Continuously ajustable temperature

The temperature can be adjusted between 50 and 150 °C. The actual temperature is displayed on a small screen.

Microheat

Thermoplastic bonding under stereo microscope

- Heat stabilizedSmallIdeal for bonding thermoplastics.

APPLICATIONS

Microheat is a small thermally stabilized hot plate combined with a power supply designed to embed samples and to bond thermoplastics under a stereo microscope. The Microheat was developed to facilitate the embedding procedure. Due to its small dimensions, it can be easily placed on the specimen table of the stereooptic microscope and in this way gluing failures can be avoided. This result is especially important in the case of samples that require bubble-free adhesion (for example, cross-section samples for electron microscopy).

OPERATION

The Model MH 4 is relatively simple to operate. The temperature of the heating plate can be infinitely adjusted over a wide range and is kept constant thanks to the integrated electronics. A control circuit maintains the temperature of the heated surface within 5 degrees Celsius. The actual temperature is displayed at the top of the tool. The temperature of the heated surface usually reaches the preset temperature in 1 to 3 minutes.

SPECIFICATIONS

- Power input: 12 V DC, 1.2 A Power consumption: 14 W Temperature range: 50 - 150 °C (continuously adjustable) Dimensions: 100 x 100 x 30 mm

SYSTEM CONFIGURATION

- Switching power supply Power input: 100-240 V, 50-60 Hz Power output: 12 V, 24 VA Microheating unit

Micropol

Polisher for small TEM and SEM samples.

Micropol is a precise mechanical specimen grinder/polisher designed for flat grinding, dimpling, thinning and polishing. High-quality samples are prepared with minimal operator effort.

- variable load electronically adjustable timer function

Variability

The load can be adjusted between 0-5 N which makes it possible to prepare extremely fragile samples.

Timer

Preparation process with the least interaction of the operator. Adjustable time scale: 0-3600 sec.

Micropol

Polisher for TEM and Metallography

- Rugged corrosion proof construction Variable speed control for precision polishing Quick change bayonet mount bowls Timer for automatic operation Extremely light load for smaller fragile TEM and SEM samples

The Micropol Polisher is a compact, versatile, electrically controlled and precise mechanical specimen grinder/polisher designed for plane grinding, dimpling, thinning and polishing of specimens in the fields of nanotechnology, semiconductors and science of the materials. The polishing parameters (speed, load, time, etc.) can be combined depending on the properties of the sample. High-quality samples are prepared with minimal operator effort.

APPLICATIONS

While Micropol MC 3 is well suited for metallographic polishing, it has been specially designed for precision TEM polishing applications. Two types of sample holders are provided with each unit, making it ideal for preparing flat and dimpled samples, respectively.

OPERATION

The Micropol arm moves the sample holder or sample itself in a semirandom geometric pattern by gently pressing it against the bottom of a container containing suitable abrasive material. The abrasive material may be emery paper or suspensions of polishing compound deposited on polishing cloth.

SPECIFICATIONS

- Power supply: 100 - 240 V AC, 50-60 Hz Power consumption: max. 85W Arm movement speed: 30 - 60 scans/min, electronically adjustable Load: 0 - 5 N, mechanically adjustable Timing: 1 - 3600 sec, electronically adjustable Maximum sample size: about 10 - 15 mm diameter Mass moved: max. 150 gramsDimensions: 251 x 220 x 181 mm

SYSTEM CONFIGURATION

- Main Unit Accessories Shipped with Kit: Flat Plastic Polishing Bowls - 4 pcs Spherical Dimple Bowls: Cu, Al, Plastic Lined, Empty Bowl - 1-1 pcs each Flat Bowl Specimen Holder - 1 pcs Spherical Bowl Specimen Holder - 1 pcs thickness measurement Starter kit of consumables (abrasive papers, polishing cloth, samples of diamond abrasive pastes and thermoplastic wax)

HSS tool

Custom made mechanical hand tools

HSS Tools

Mechanical sample preparation prior to dilution requires custom-made mechanical hand tools. With four practical and reliable parts, this kit has been designed based on the practical experience of many users. Some of the tools are suitable for adjusting the sample pieces on the Ti discs, others for removing excess glue and cutting, or adjusting the base plate of the sample holder.