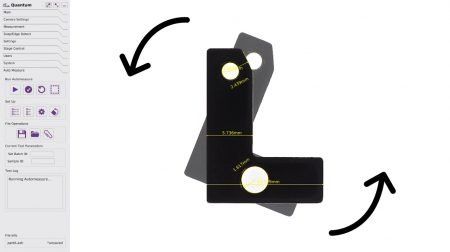

Intuitive User Interface - Program And Test

Program

There Are 6 Easy Steps To Allow You To Program Your Parts/Setup Your Measurements.

Step One: Open new part

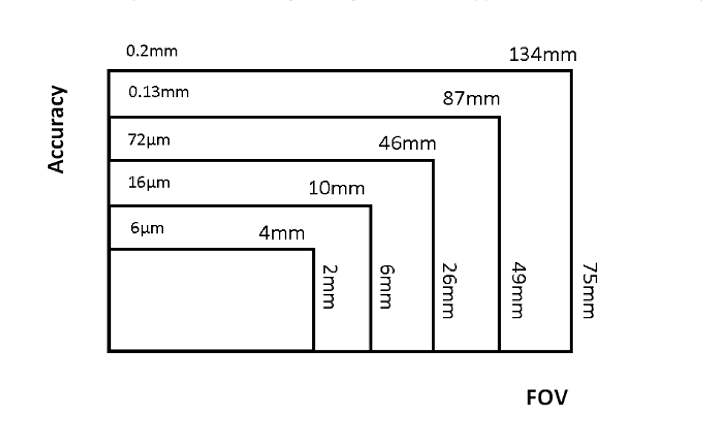

Step Two: Select Field of View which best suits the size of the part

Step Three: Set focus point

Step Four: Set the optimal lighting conditions for the part

Step Five: Define the edges of the part to ensure readiness for measurement

Step Six: Ready to perform measurements as outlined in the Measurement Suite section

Test

The Test Option Allows You To Perform Automatic Testing Of Production Parts.

Test your part against a master golden template to automatically identify defects.

Simply load the test part, run the test and the results are clearly displayed on the screen. Results can be captured and exported to an Excel document for documentation and traceability.

Quick Measurements & Data Sharing

Save and recall measurement and settings files for routine inspections.

Simultaneous automatic measurements to speed up inspection time.

PASS/FAIL tolerance judgement display for rapid identification of failures.

NFS connectivity for automatic transfer of results to the network.

Documentation and traceability.

Measurement Suite

Quantum has a wide range of measurement capabilities, such as Horizontal Dimension, Vertical Dimension, Horizontal Dimension 2 Point, Vertical Dimension 2 Point, Dimension 2 Point, Dimension (not axis tied), Best Line Fit with Dimension, Best Fit Circle with Dimension Diameter, Angle, Angle without Origin, Spline, 3 Point Arc with Radius Dimension, Polygon Area, 3 Point Perpendicular Dimension.

Horizontal Dimension

Allows the user to draw horizontal dimension measurements

Vertical Dimension

Allows the user to draw vertical dimension measurements

Dimension (Not Axis Tied)

Allows the user to measure a dimension without an axis

Best Line Fit With Dimension

Aids users to define the length of a part with an uneven edge

Angle

Allows the user to measure angles (angle with origin)

Horizontal Dimension 2 Point

2 Point Horizontal Measurement. Does not require mouse left click hold and drag

Vertical Dimension 2 Point

2 Point Vertical Measurement. Does not require mouse left click hold and drag

Dimension 2 Point (Not Axis Tied)

Allows user to measure a dimension on any axis. Does not require mouse left click hold and drag

3 Point Perpendicular Dimension

Allows the user to measure the perpendicular distance between two planes

Spline

Allows the user to measure samples with non-linear lengths

Angle Without Origin

Allows the user to measure an angle without the need for a defined origin (useful for measuring parallelism of a part)

3 Point Arc With Radius Dimension

Allows users to define and measure the radius of an arc

Best Fit Circle With Dimension

Allows the user to define multiple points on a circle radius measurement. The greater the number of points defined the greater measurement accuracy

Best Fit Circle With Dimension Diameter

Allows the user to define multiple points on a circle diameter measurement. The greater the number of points defined the greater measurement accuracy

Polygon Area

Allows users to define and measure an area of an irregular shape. Particularly useful for the polymer industry, such as measuring the area of a wire shielding section

Skew

Allows the user to set part alignment correction to the X axis on a part that has been placed in the FOV. Quick and accurate horizontal or vertical measurements with confidence.

Datum

Datum can serve as a reference check to provide a precise depiction of a part, feature or an enhanced understanding of feature to feature relationships.

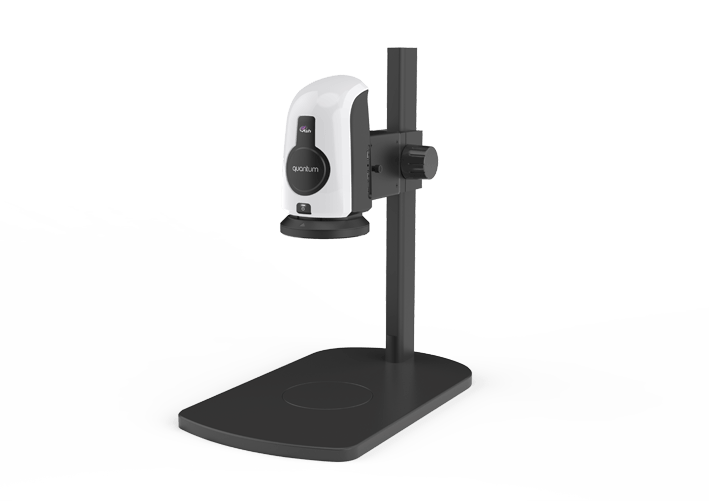

Automatic Alignment

Automatic identification of part position & re-orientation: No need for a jig to position parts.

The position of a part is automatically identified and re-orientated to its programmed measurement position.

QUANTUM Image gallery

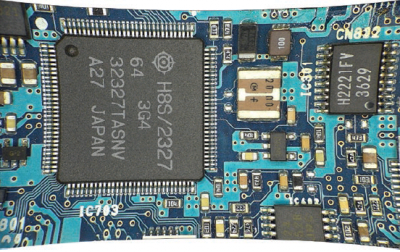

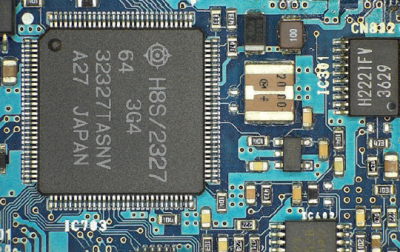

RTLDC™

Real Time Lens Distortion Correction (Patent Applied For)

Unique Technology

Distortion is inherent in all lenses. Rather than correct this through optics, Ash have developed a digital solution. Quantum uses advanced algorithms to correct lens distortion on the live image. This results in consistent measurements across the entire field of view.

Before

After