GERMAN products

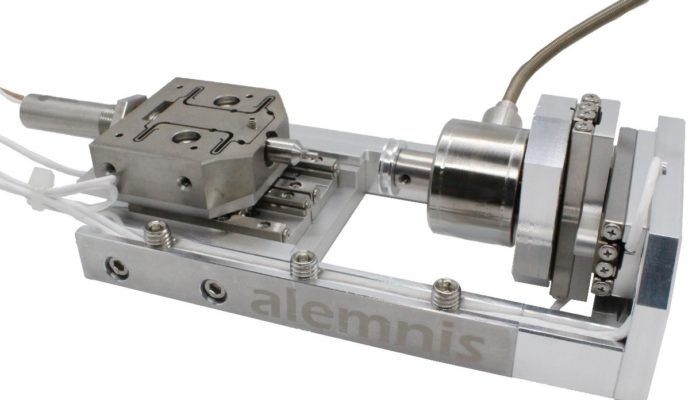

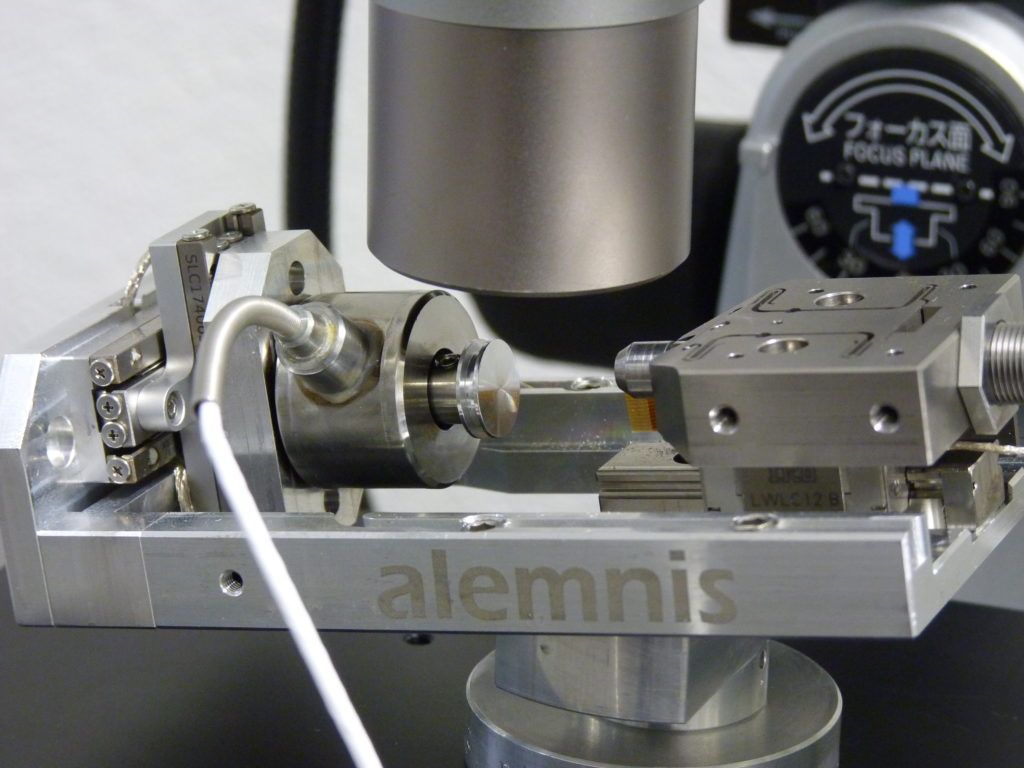

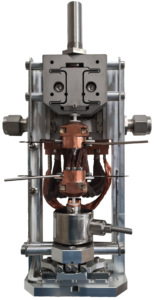

Alemnis Standard Assembly (ASA)

Alemnis pushes the boundaries of numerous nanomechanical test methods with a high-precision nanoindenter (ASA) assembly and a range of complementary accessories, consumables and controllers.

Unique modular design:

The Alemnis Standard Assembly (ASA) is a modular indentation platform designed to be customized to your specific needs. Its unique modular design makes it the world's most versatile, high-performance and cost-effective instrument and it is used in some of the world's most prestigious universities and research centers.

An important milestone in the scientific community:

It is based on years of experience in the design of scientific instruments and piezoelectric transducers carried out in joint projects between EPFL (Swiss Federal Institute of Technology, Lausanne) and Empa (Swiss Federal Laboratories for Materials Science and Technology, Thun). A publication by the inventors received the 2004 Bunshah Award from the American Vacuum Society. It is considered an important milestone in the scientific community.

Configurations: Unmatched Versatility

IN SITU

In SEM

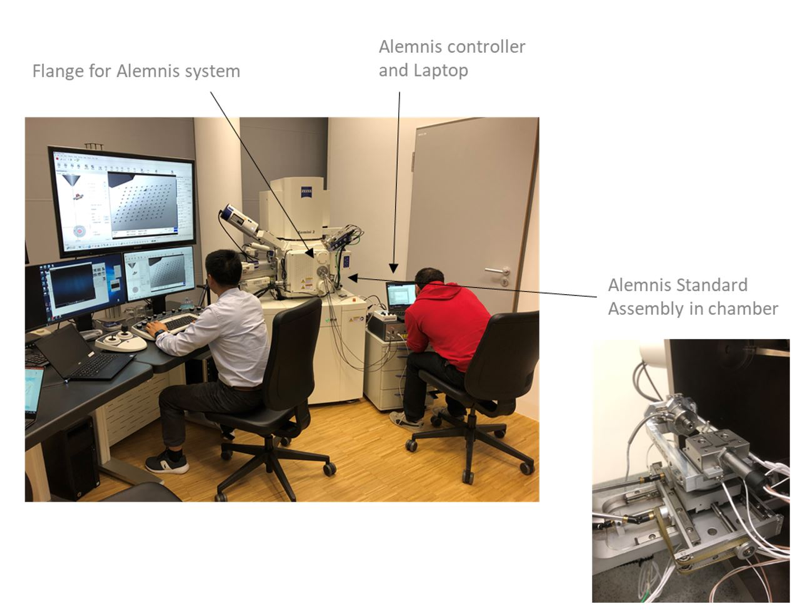

The Alemnis Standard Assembly (ASA) comes with a custom flange and mounting adapter for installation on any scanning electron microscope (SEM) with a large enough camera.

Typical on-site SEM setup: cables from the ASA are routed through a cable tie to the controller and a laptop is provided as well as a SmarAct controller for XYZ offset.

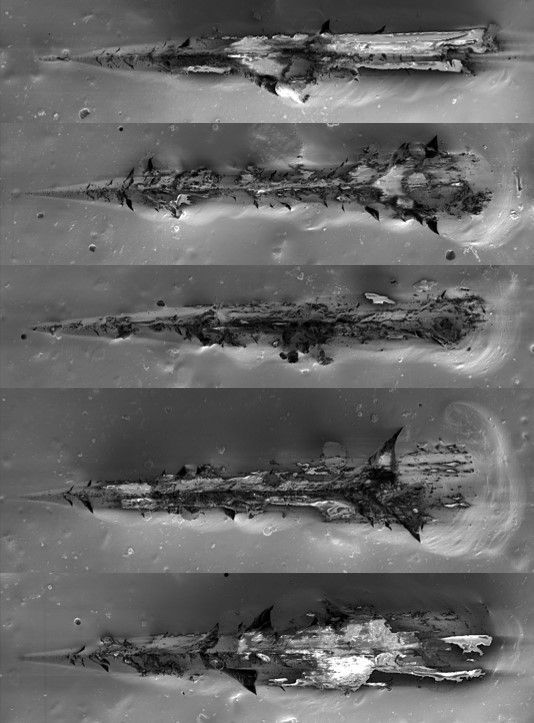

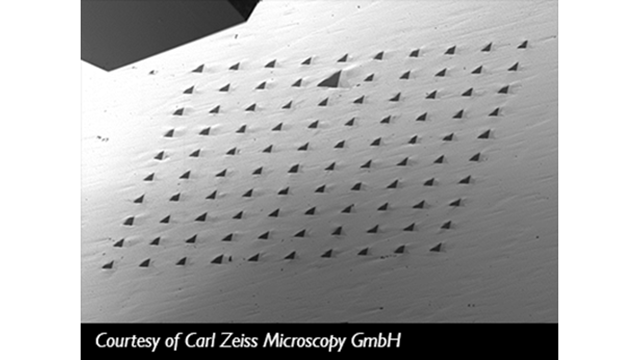

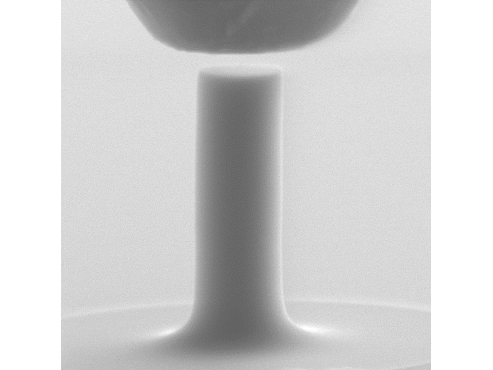

ASA is being prepared and used within a scanning electron microscope (SEM) to test a micropillar produced by focused ion beam (FIB) milling. At the end a quasi-static column compression test and a fatigue test (cyclical oscillation) are shown.

EX SITU (as an independent instrument)

Be unique

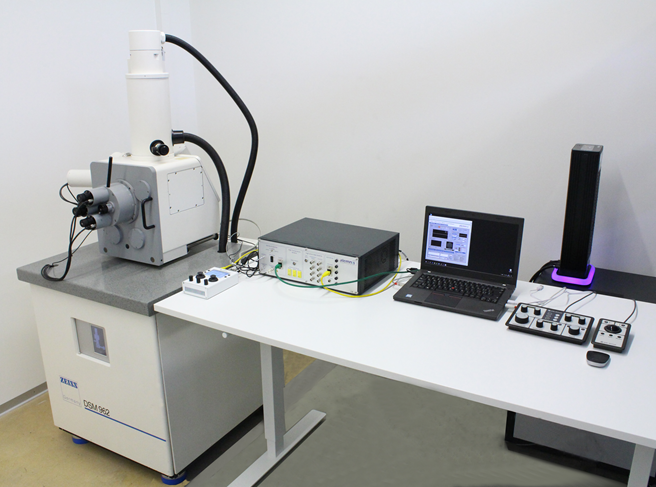

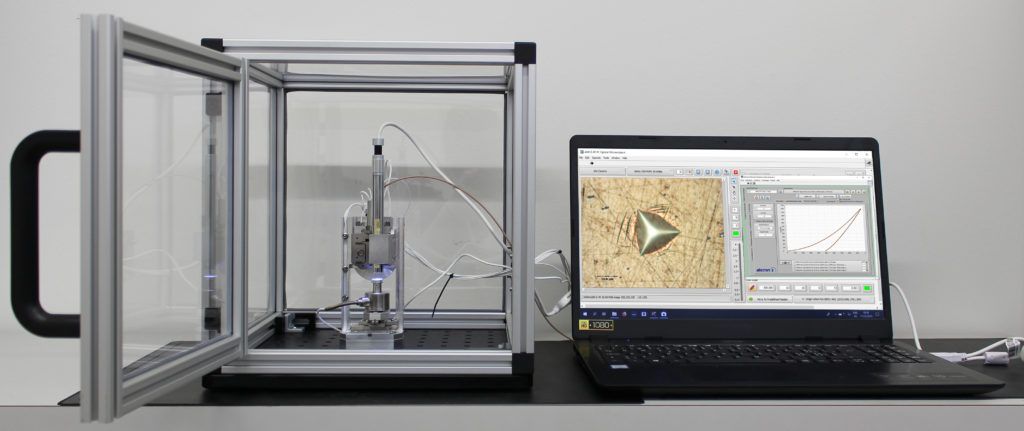

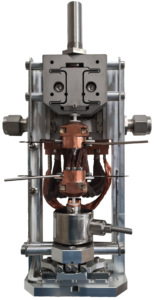

The Alemnis Standard Set (ASA) can be used as a stand-alone micromechanical test system on any rugged lab bench. For such ex situ operation, it is recommended to place the ASA in a dedicated cabinet and place the cabinet on an anti-vibration table to minimize noise.

Example of ASA in stand-alone upright configuration with integrated microscope (IMI) and standard cabinet (ENC)

The ASA can also be mounted under a light microscope, providing a side view for experiments under ambient conditions. This setting is typically used for materials that cannot be tested in the SEM. Many users combine the ASA with a light microscope that has a long working distance objective to facilitate sample alignment and postmortem analysis. This also allows a wider range of mounting angles to be used.

Examples of an ASA mounted under a light microscope with a long working distance objective.

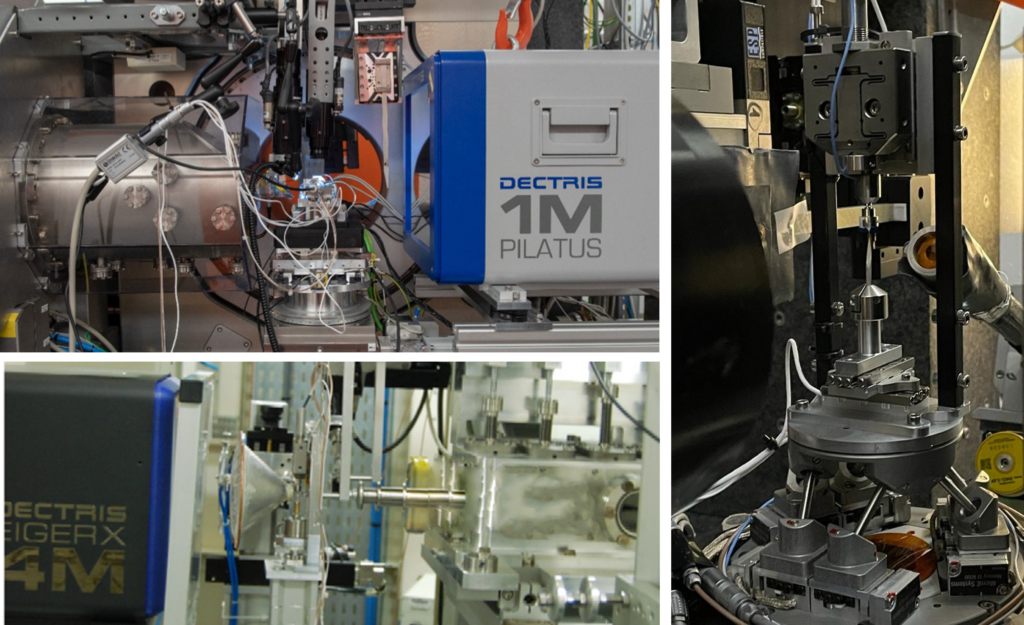

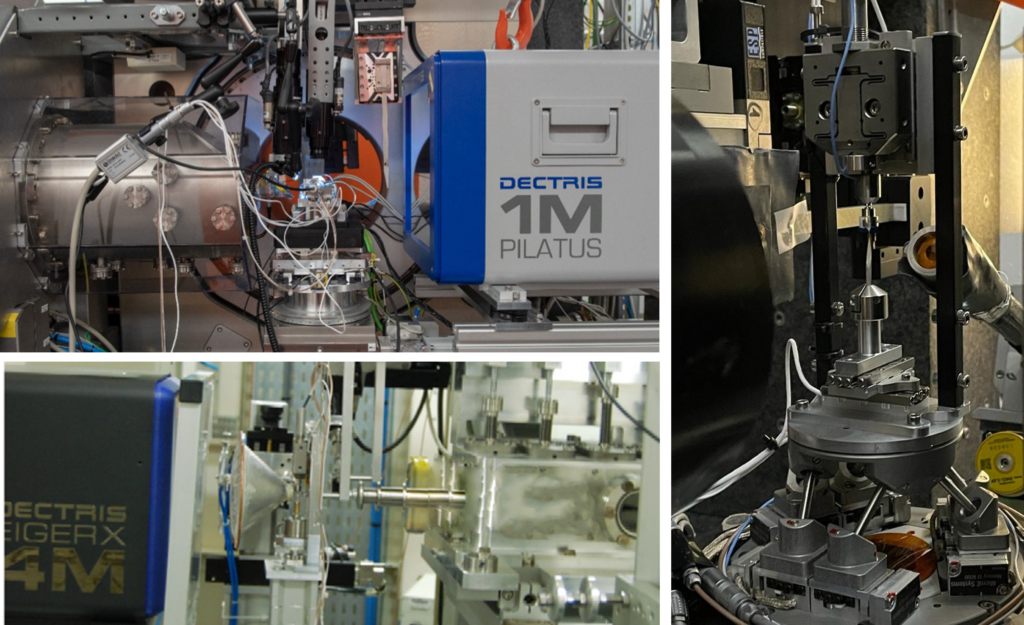

IN SYNCHROTRON

SYNCHROTRON/X-RAYThere are several challenges in designing an in situ mechanical test suite compatible with synchrotron beamlines. The assembly must be lightweight as it often has to be mounted on top of several movement stages. In addition, the weight of the load frame must be distributed as symmetrically as possible with respect to the axis of rotation. In addition, the assembly must be open enough to allow unrestricted passage of the X-ray beam.

The Alemnis Standard Assembly (ASA) meets all of the aforementioned compatibility requirements: it is lightweight yet rigid, symmetric about the axis of rotation, and has a very open architecture that is more than sufficient for experiments on static beamlines. For specific angles or for full rotational tomography, the lateral frame elements can be replaced with an x-ray transparent material (eg, polyether ether ketone, or PEEK).

Alemnis Standard Array (ASA) mounted in various configurations on synchrotron X-ray lines. (Photos courtesy of S. Kalbfleisch, MAX IV Laboratory, Lund, Sweden, and X. Mäder and A. Groetsch, Empa, Thun, Switzerland)

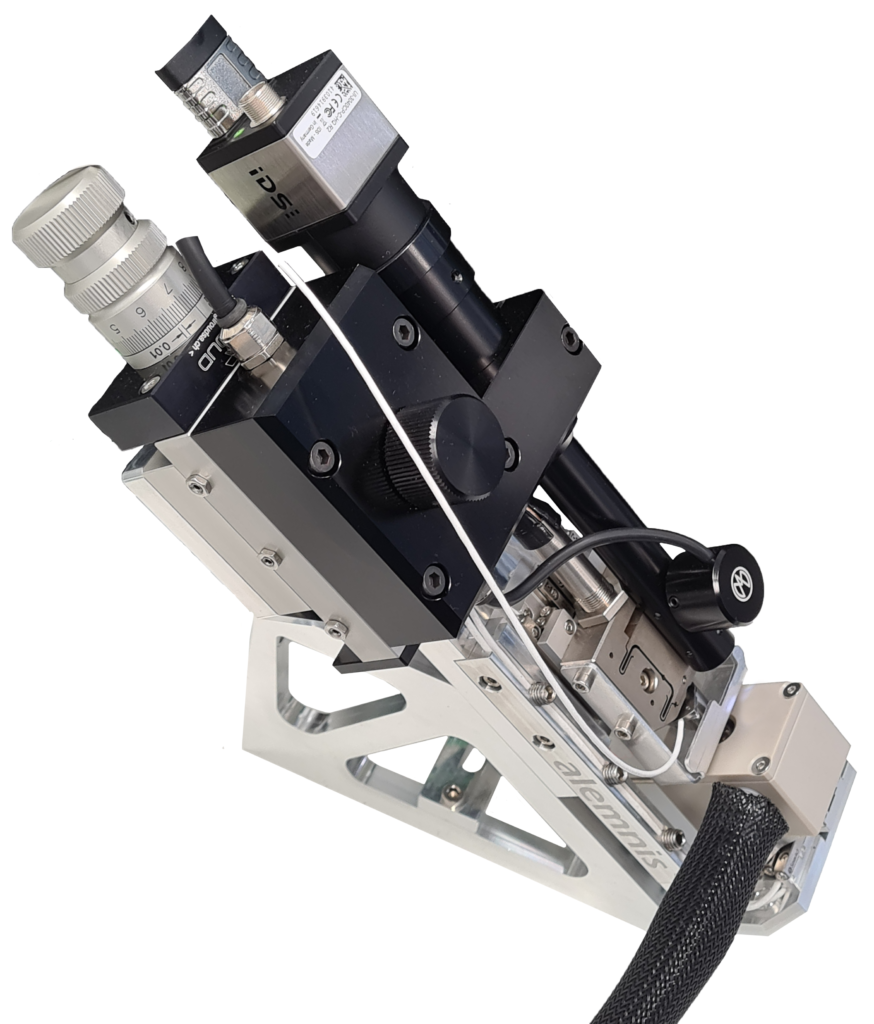

The ASA can also be mounted in conjunction with an Integrated Microscope (IMI), which is an optical microscope with integrated illumination and allows repositioning accuracy between the indenter and the focus point of 10 µm. The combination of nanoindentation with X-ray diffraction (XRD) in a synchrotron beamline allows the study of many material properties. For example, a common experiment involves placing the sample under some constant stress (usually achieved by holding the applied load for several hours) and mapping the induced elastic strain field in the strain zone. These studies may pave the way to study strain profiles using synchrotron radiation during small volume micromechanical testing. In this way, the nanostructural origin of the observed deformation evolution can be understood and correlated with the deformation conditions.

TOMOGRAPHY

Tomography

There are several challenges when designing an in situ mechanical test suite compatible with X-ray lines for computed tomography. The assembly must be lightweight as it often has to be mounted on top of several movement stages. In addition, the weight of the load frame must be distributed as symmetrically as possible with respect to the axis of rotation. In addition, the assembly must be open enough to allow unrestricted passage of the X-ray beam.

The Alemnis Standard Assembly (ASA) meets all of the aforementioned compatibility requirements: it is lightweight yet rigid, symmetric about the axis of rotation, and has a very open architecture that is more than sufficient for most experiments. Additionally, the compact nature of the ASA means that the sample can be brought closer to the X-ray source, improving image resolution. For specific angles or for full rotational tomography, the lateral frame elements can be replaced with an x-ray transparent material.

Example of an X-ray tomography measurement made on a polymer foam (5mm wide, 7mm high) that has been deformed by a square of fused silica (3 x 3mm) held at 10% tension for 12 hours of image acquisition. cycle (3 µm image resolution)

Alemnis Standard Assembly (ASA) mounted vertically on a commercial X-ray tomography system.

The ASA can be easily mounted on most commercially available tomography systems, either statically or on a swivel allowing full rotational tomography. A typical experiment might consist of deforming the sample material to a predefined deformation level using displacement mode.

This stress can then be maintained constantly throughout the imaging cycle and any load changes recorded by the load cell (effectively a stress relaxation experiment). It should be noted that a high-resolution 3D rotational tomography image can take 10 hours or more to complete, so the inherently high structural rigidity of ASA is particularly useful for maintaining stability throughout the imaging cycle.

The choice of indenter material is also important because a large discrepancy in X-ray absorption between the indenter material and the sample material can affect the contrast of the resulting image. The indenter must also be adapted to the size scale of the material being investigated.

True scroll mode

The unique performances of ASA's real scrolling mode are the key to understanding:

- Load drops Compression artifacts Strain rate jumps Sudden load leaks in real time

Wider charging range

Widest load range on the market: From µN to 4 N

Environmental control options

The ASA allows materials to be tested in a wide range of environments with options including:

- High temperature up to 1000°C

- Low temperature up to -150°C

- Relative humidity control

- Liquid cell

- Bioindenter

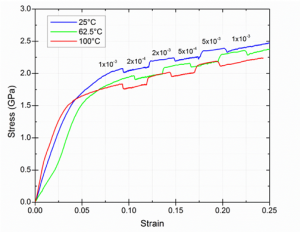

High temperature up to 1000°C

HIGH TEMPERATURE MODULE (HTM-1000)

The Alemnis High Temperature Module (HTM) combines high performance, precise temperature control and time-proven robustness. Individual temperature control of the sample and indenter tip ensure perfect temperature adaptation, which is essential to reduce thermal drift to a minimum. The mechanical design is fully symmetrical to further minimize differential thermal expansion and drift. To achieve the best value for your application, we offer three models that cover temperature ranges up to 400°C (HTM-400), 800°C (HTM-800) and 1000°C (HTM-1000). All models have a temperature control accuracy of < 0.1 °C.

The high temperature modules can be adapted to the standard set of Alemnis. It can also be used in air up to 200°C. However, for higher temperatures, the indenter must be operated in a vacuum (for example, inside a SEM). To ensure safe and reliable operation, our high-temperature models are actively water-cooled to keep the load sensor and actuation head at 25°C, while thermal protectors reduce the amount of radiative heat loss to provide efficient heating.

Low temperature up to -150°C

LOW TEMPERATURE MODULE (LTM-CRYO)

The low temperature module (LTM-CRYO) can be adapted to the Alemnis standard assembly (ASA).

It can be used in air, but condensation can form on the sample surface, so ideal operation should be in a vacuum (for example, inside a SEM).

The LTM-CRYO has been continuously improved since its first release in 2018, making it the most established cryogenic choice for in situ micromechanics.

Characteristics:

- -150°C to 210°CIndependent sample and tip temperature controlThermal stability /- 0.1°C

Relative humidity control

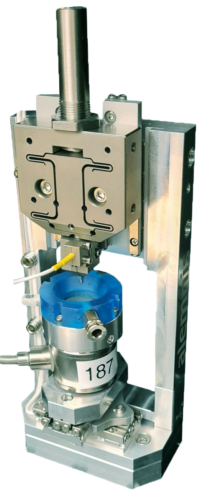

RELATIVE HUMIDITY MODULE (RHM)

The Relative Humidity Module (RHM) is an environmental sample chamber that allows mechanical tests to be performed under controlled humidity and temperature conditions or in liquid (sample completely submerged).

The typical configuration of the ASA is mounted vertically with the indenter on the specimen, but other configurations are also possible depending on the options installed.

Relative humidity (RH) can be controlled in the range of 5 to 95% with an accuracy of 1.5%. The temperature range is from room temperature to 70°C with an accuracy of 0.1°C.

For completely submerged tests without relative humidity and temperature control, the Liquid Cell (LIC) can be used.

Liquid cell

LIQUID CELL (LIC)

Liquid Cell (LIC) can be used for a wide range of experiments where the sample must be immersed in liquid. Therefore, it is used ex situ with the Alemnis Standard Assembly (ASA) mounted vertically and the LIC mounted on the load cell.

Some examples of how the LIC can be used are:

- Immerse biomaterials in saline or body-mimicking fluid (BMF) to assess their mechanical properties when hydrated.

- Electrochemical tests where the indenter can be used as a current probe and the electrolyte (liquid) can be activated using an external potentiostat for corrosion or passivation studies.

- Studies of the mesoporous effects of the hydrogel, that is, how the mechanical properties change depending on the level of hydration.

- Tribological studies of interaction between the indenter and the sample when immersed in lubricant (liquid oil or grease)

Bioindenter

BIOINDENTER (IBIO)

The Bio-indenter is an ex situ variant of the Alemnis Standard Set (ASA) that is specifically designed to characterize the mechanical properties of tissues and soft materials.

It can be configured with the Relative Humidity Module (RHM) and Miniaturized Load Cell (MLC) to provide a complete test platform for a wide variety of sample configurations (micropillars, particles, gels, tensile tests, etc.) in a range of environments (controlled relative humidity and temperature, submerged in liquid, etc.).

The basic specifications are as follows:

Applied load range: 10 µN – 500 mN (by choosing a different load sensor, the maximum range can be extended up to 4 N)

Load noise floor: 4 µN

Displacement range: up to 100 µm (using DHP-100)

Displacement noise floor: 1 nm

The Bio-indenter setup can also be coupled with a light microscope via a piezoelectrically driven XY displacement stage.

The optical microscope has the following specifications:

- Zoom objective (0.77 – 9.31x) Working distance 86 mm Color camera 1280 x 1024 pixels Coaxial and ring lighting.